Technological evolutions are gradually leading us to more comprehensible market places as consumers. The shift in this scenario has transformed and intensified the R & D activities to deliver High Performance products for various sectors of the economy. Equipping industries with futuristic technology is clearly, the need of the hour.

With state of the art designs and awakening of the textile industry to modern trends, we observed the emergence of High Performance Textiles.

Introduction To High Performance Textiles: The Making and Usage.

High performance fibres have irreplaceable market positions under various areas of application. The textile fibres that are used for manufacturing high performance products are in an increasing demand in the Global Market. Due to their mechanical properties, outstanding abrasion resistance, fatigue, chemical resistance and cut resistance they help creating the most durable and damage resistant products.

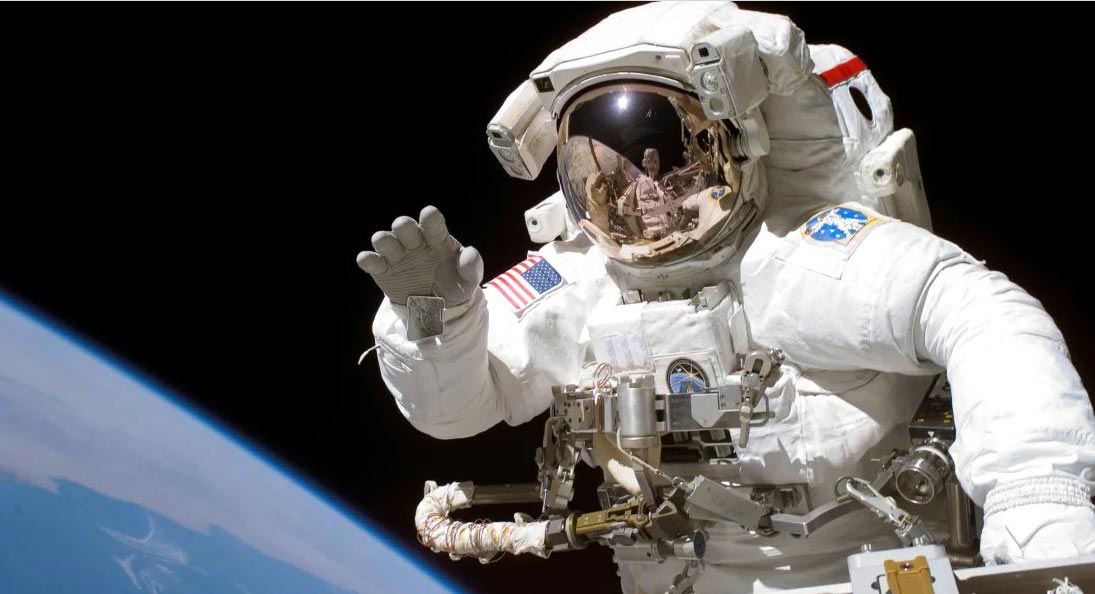

Various polymers find their prestigious place in the high tech applications such as the manufacturing of spacecrafts, composites, etc. In such applications weight reduction is one of the major concerns. Development of lightweight, high modulus textile structures produce outstanding products with superior quality.

Usage of high performance textiles is also observed in the manufacturing of insulating materials which are applied fire resistant areas.

Various fibres like High performance Polyethylene, Aramide, Glass fibres, Polyether ketone, Arimide and other polymers are in high demand due to their chemical resistance.

What Sets Them Apart?

It is the strength and stiffness the High Performance Textiles exude, that sets them apart and hence they are preferred over various fabrics for more perilous applications.

High performance fibres contain a range of favourable properties such as high modulus; high strength and low density. They can also easily withstand high temperatures. Due to these properties they are widely used in Aerospace, Nuclear Biological Chemical warfare protective clothing and Ballistic armor applications (Bullet proof jackets, Helmets etc).

Pre industrial fibres, such as cotton, wool and silk typically have tenacities between the range of 0.1 0.4N/tex and initial modulo from 20 to 5N/tex/s. Excluding silk, they are all short fibres, so the conversion efficiency to yarn and fabric strength is relatively low. Some of the earliest regenerated cellulose fibres, such as viscose rayon and acetate, had strengths in cellulose fibres. Continuous filament rayon yarns such as Tenasco, with strength of 0.4N/tex, was introduced for use in tyre cords.

What is their Global Market Share Over The Decade?

The global high performance fabric market is estimated to reach a market size of USD 79.55 Billion by 2020.The increasing Global awareness regarding personal hygiene and physical fitness are the major forces that drive the market.

The market share is currently increasing due to various technological developments in the textile industry.

High performance fabrics are expected to observe an increasing demand in the North American region due to various healthcare advancements. The retrieval of the infrastructural and industrial sectors is also empowering the growth of the market.

The antimicrobial segment in the market is estimated to be the fastest-growing application for performance fabrics during the period of observation.

The high performance fabric market is usually analyzed in terms of revenue (USD) and volume (Million Square Meter) across all the major regions namely, North America, Asia-Pacific, Europe, South America, and the Middle East & Africa.

It has been observed that High Performance Textiles replace the traditional usage of metals in places where light-weight spare parts are desired. This fibre has the potential to participate in the increasingly innovative technological advancements.