What exactly is recycled polyester?

There has been an increase in fabric made using polyester fibers derived from recycled plastic bottles (PET). This is a significant victory when considering that virgin polyester isn’t an exceptionally environmentally friendly raw material.

Many different sectors use recycled polyester to make clothing. It is a highly versatile fiber that is also environmentally beneficial. To provide environmentally friendly textiles for any business, ColossusTex uses recycled polyester in its Eco green line of eco-friendly materials.

Eco-friendly designs rely heavily on recycled materials like recycled polyester. A smaller environmental footprint and the European goal of being carbon neutral in 2050 are achieved through these products. Newly manufactured textiles should contain at least 30% recycled materials by 2030, according to one of the Dutch government’s goals.

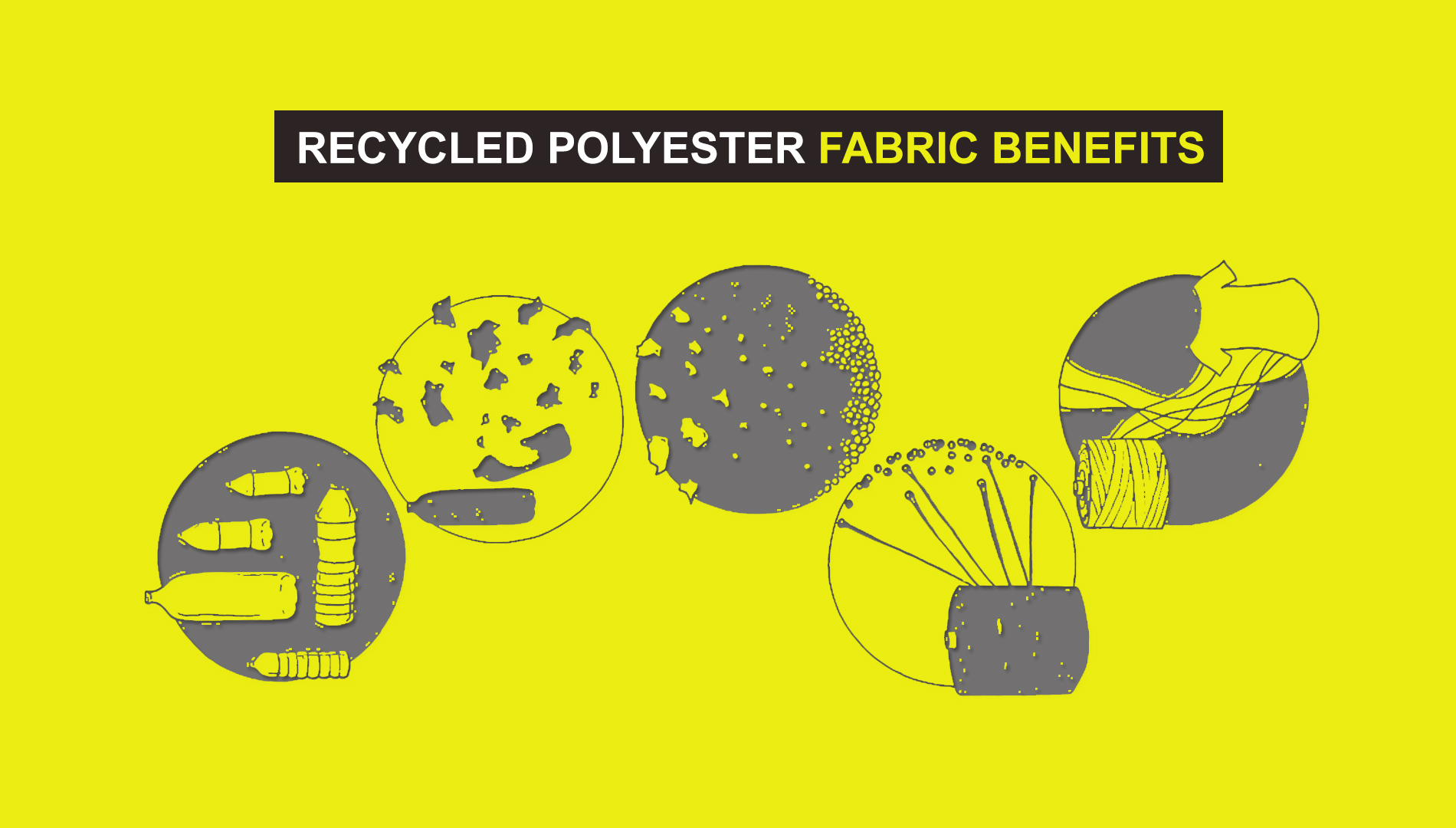

What is the process of polyester recycling?

To make PET yarn, PET bottles are collected, cleaned, and broken down into smaller pieces, which are then spun into yarn that may be altered to include performance technologies such as moisture-wicking and temperature regulation, among others.

Recycled polyester can be produced using two different methods.

Polyester chips are produced mechanically by mixing water from plastic bottles with the substance. A typical fiber production method is then utilized to turn the polyester chips into high-quality recycled polyester material that can be used to produce clothing and other products.

Existing Polyester clothing is the center of the chemical procedure, which can be completed in a shorter amount of time. To begin with, the clothing is shredded into small pieces, spun into new polyester yarn, and woven into gorgeous fabrics that will be sold.

What are some benefits of recycled polyester?

PET bottles are just one example of the growing plastic waste problem in our environment and society. We need to use solely rPET in our collections and environmentally friendly support brands.

- By using recycled polyester can conserve a significant quantity of water and energy. Compared to virgin polyester, up to 62 percent less energy and 99 percent, less water is required to make one kilogram of recycled polyester fabric. Carbon dioxide emissions can be reduced by up to 20 percent with rPET.

- rPET generates less waste. Up to a third less waste is generated by recycled polyester since it is created from post-industrial waste or other post-consumer plastics such as discarded textiles or ocean trash.

- Chemical and refinery extraction are no longer necessary when using recycled polyester. Plastic PET bottles are required for the product’s production.

- Recycling synthetic materials has many benefits beyond the fact that they can be reused. Mold, mildew, dust, and bacteria can be kept out of a home using recycled polyesters. Mold spores can be kept off the furniture and other surfaces with their guidance and mold growth on fabric can be prevented with their assistance. Rugs and flooring, as well as other household items, can be protected in this way.

- Last but not least, marine life and ecosystems are put at risk by plastic rubbish that ends up in the oceans. In this chilly and humid environment, decomposition can take thousands of years.

Conclusion:

Cutting and chopping old plastic water bottles yields ColossusTex’s recycled polyester or rPET. After that, the polyester fiber is melted down and spun into new fibers. Recycled polyester fabric collections can be made from recycled yarn.